cold forging

forging auto parts

forging electrical tool parts

forging bicycle parts

IATF16949 certificated forging factory

-

Company profile

Li-Hsing is a ISO 9001:2015 and IATF16949:2016certified automotive and motorcycle parts manufacturer.

Founded in 1984 by Rong-Hua Jiang, the president of the company, we have successfully accumulated a lot of experience in cold forging and mass production of customized forgings over time. We have sawing machine, spheroid annealing furnace, surface phosphate treatment line, forging machine, high-frequency heating furnace, etc., all will be completed in Li-Hsing, no need to outsource processing.At the same time, we have the ability to design and make our own die. We rely on our past forging experiences to design die. We also use forging simulation software to shorten the time for new product development.

Die making equipment includes CNC turning, wire cutting, and electrical discharge machine.

Once the die is designed, we can immediately start the die making process to shorten the die making time for

the newly developed products.

Our products include auto parts, power tool parts, air tool parts, motorcycle parts, sports equipment parts,

mechanical hardware parts, aluminum alloy parts, traditional bicycle parts, electric bicycle parts, etc.

Product

Bicycle Parts

Bicycle Parts

Motorcycle Parts

Motorcycle Parts

Auto Parts

Auto Parts

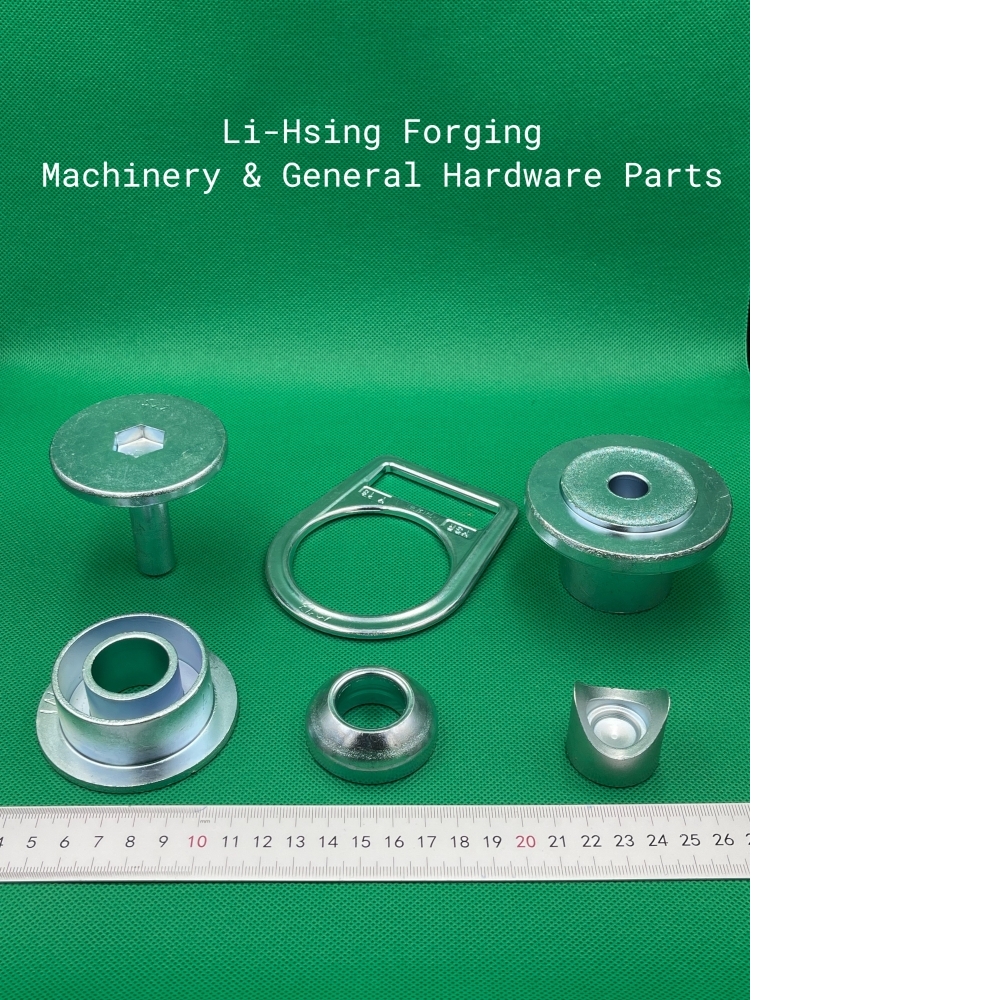

Machinery & General Hardware Parts

Machinery & General Hardware Parts

Hand Tool Parts

Hand Tool Parts

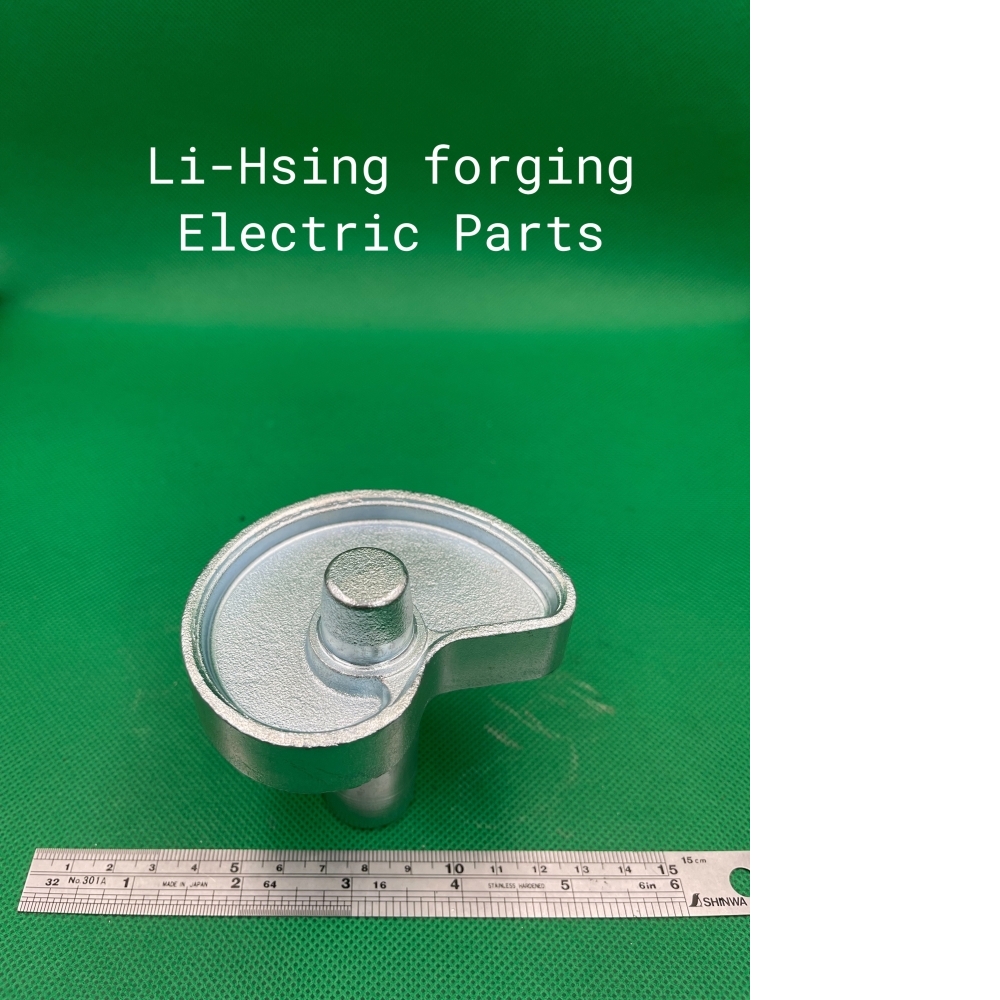

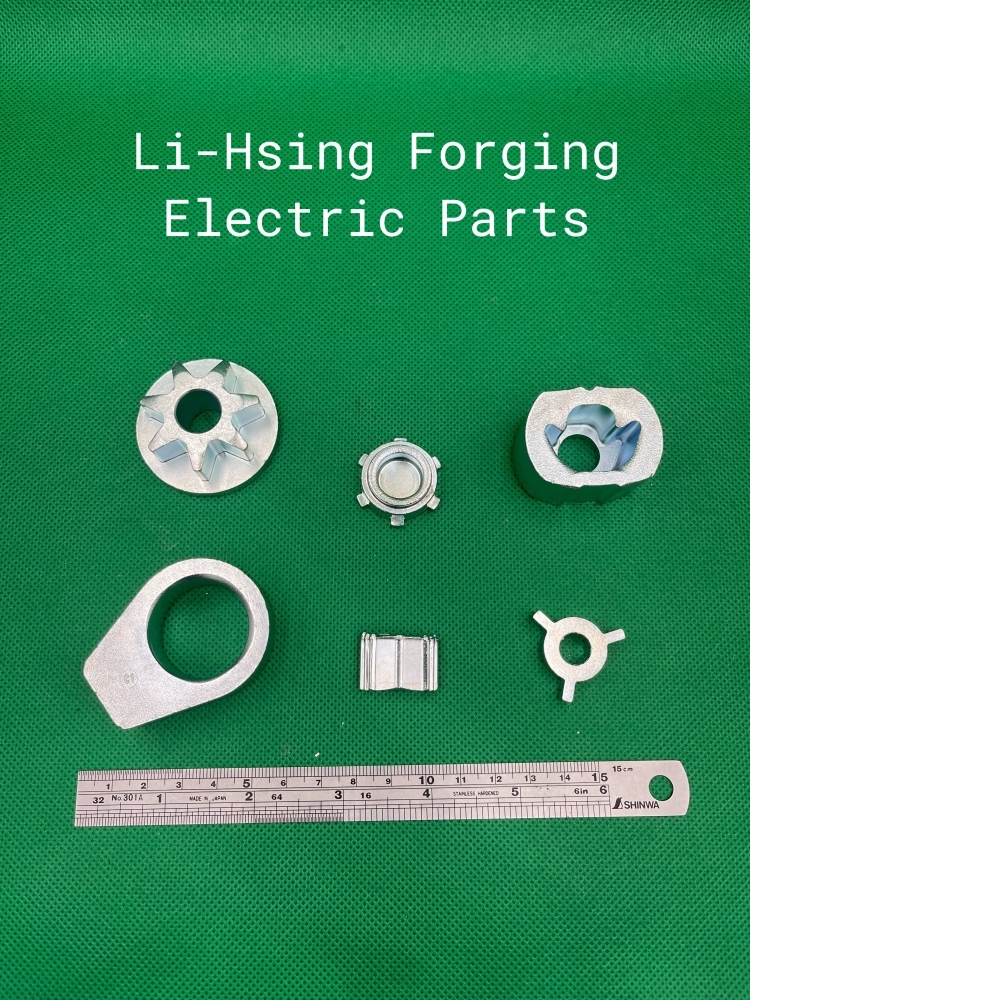

Electic Parts

Electic Parts

Gear Parts

Gear Parts

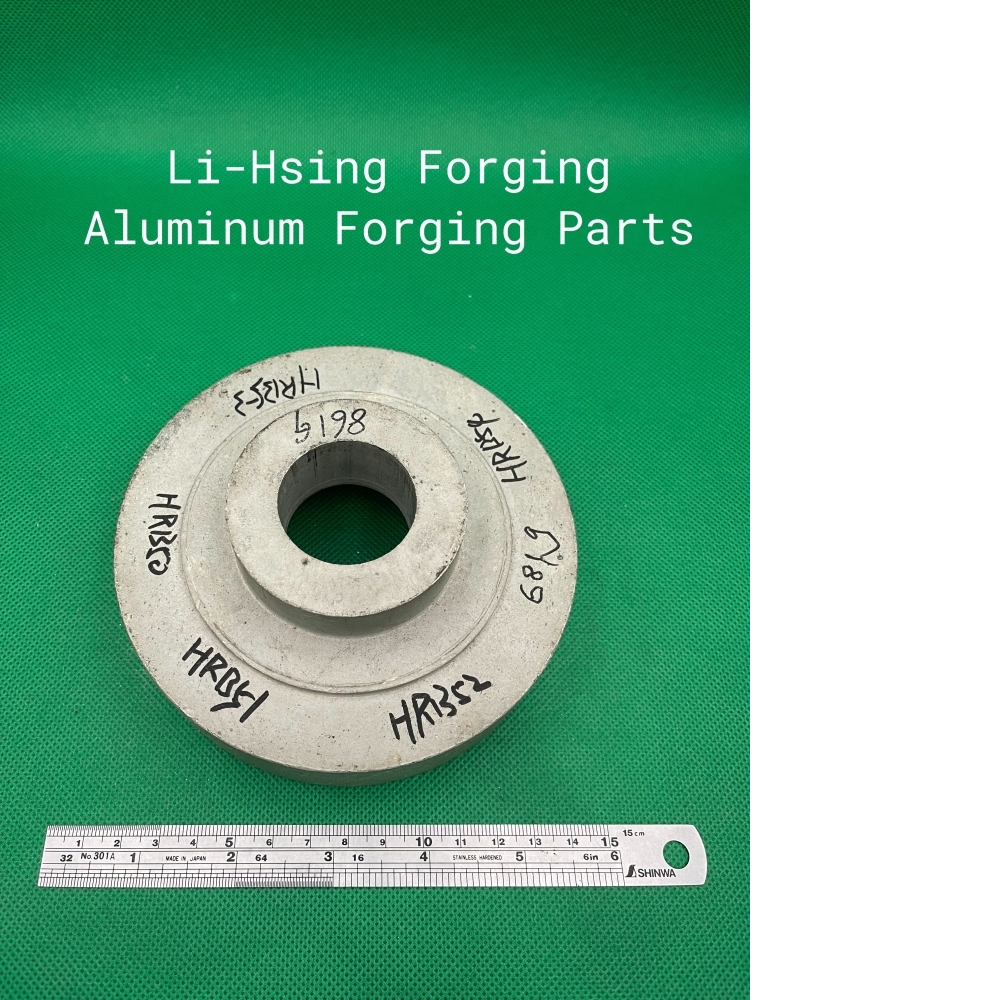

Aluminum Forging Parts

Aluminum Forging Parts

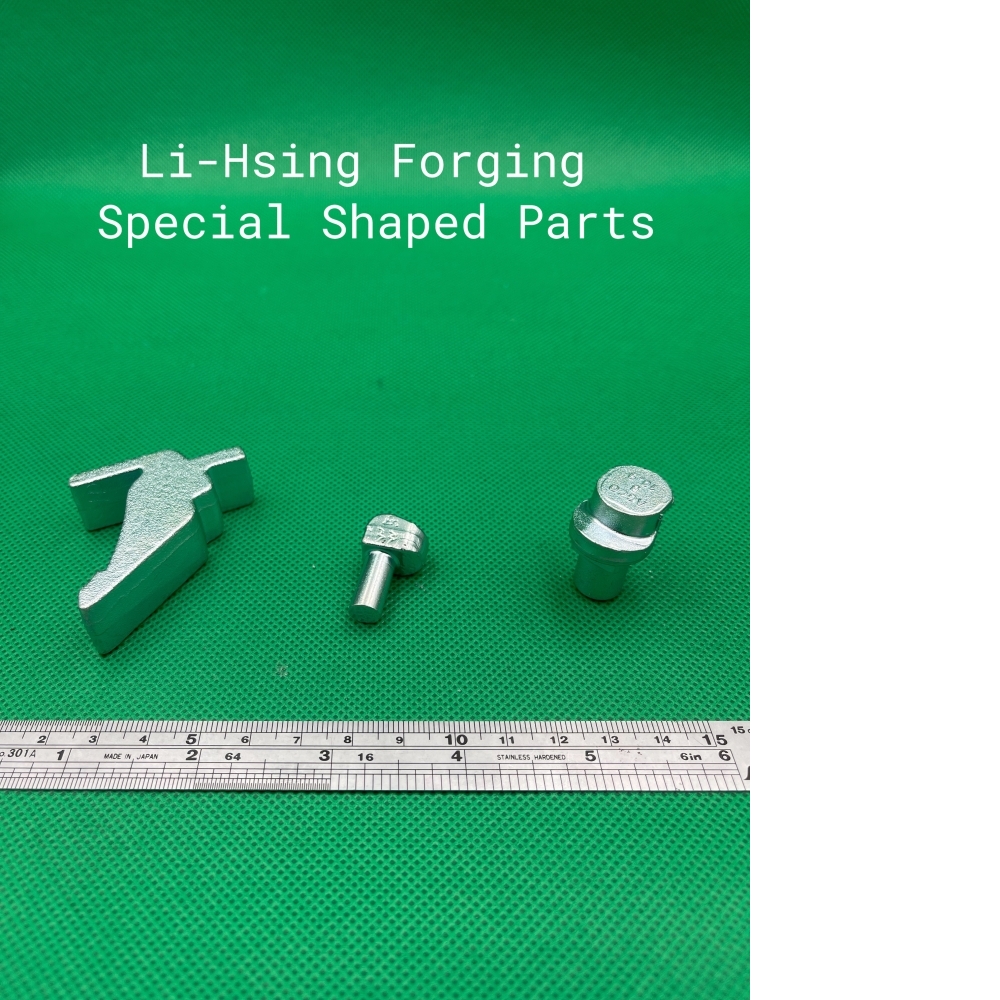

Special Shaped Parts

Special Shaped Parts

Company History

-

2022

Update the website and change it to a responsive website.

-

2020

Li-Hsing was qualified by the Ministry of Science and Technology to enter the Er-lin Central Science Park.

-

2019

Li-Hsing team has successfully passed ISO9001:2015 and IATF16949:2016 international certifications after counseling and has become an internationally qualified auto parts manufacturer.

-

2018

Through special die base to achieve 3D forging technology, we have successfully mass-produced warm forged parts.

-

2014

Successfully developed power tool hammerhead parts.

-

2008

Li-Hsing has become a TS 16949:2009 certified forging metal parts manufacturer.

-

2006

Li-Hsing moved into our current manufacturing plant. Our new manufacturing planet quadrupled in size.

-

2003

Li-Hsing purchased the current manufacturing facility located at Gong-ye-cyu (Industrial Park), Taichung City, Taiwan. Li-Hsing purchased a significant number of new quality assurance equipment, cold forging presses, and annealing furnaces.

-

2000

Li-Hsing has become an ISO 9001:2008 certified forging metal parts manufacturer.

-

1997

Li-Hsing purchased a new manufacturing facility in Taichung City, Taiwan. Our new manufacturing planet doubled in size. Li-Hsing continued to invest in the latest technology by purchasing new cold forging presses and machineries.

-

1994

Li-Hsing invested heavily in production automation and unmanned cold forging presses. Li-Hsing also has purchased cold forging presses from Japan. This new technology enabled Li-Hsing to produce high quality products and use alloy steel efficiently.

-

1988

Li-Hsing's business quickly expanded. Li-Hsing's products were exported to many parts of the world, including United States, Japan, and Europe. Li-Hsing purchased 10 new set of cold forging presses to produce automotive parts and tools.

-

1984

Li-Hsing Forging Enterprise Co., Ltd. was founded in 1984 by Mr. Jung-Hua Chiang as a privately held metal forging and stamping company. Mr. Chiang is one of the leading experts in the metal forging and stamping industry.

Professional Equipment

-

Cold Forging Equipment Tonnage Amount 11200 tons 1 1000 tons 1 650 tons 6 400 tons 13 250 tons 1 160 tons 6 Under 160 tons 6

-

Shearing Equipment Machine Amount Cropping Machine 3 Sawing Machine 3 Steel Coil Cutting Machine 2 Sheet Metal Cutting Machine 2 - - - - - -

-

Surface Treatment & Annealing Equipment Machine Amount Sand Blasting Machine 2 Automatic Phosphatizing Line 1 10-Ton Annealing Furnace For Steel 3 2-Ton Annealing Furnace For Aluminum 1 2- Ton Annealing Furnace For Steel 6 - - - -

-

Latest Product

Latest Product -

Machinery & General Hardware Parts詳細資料

Machinery & General Hardware Parts詳細資料 -

Machinery & General Hardware Parts詳細資料

Machinery & General Hardware Parts詳細資料 -

Special Shaped Parts詳細資料

Special Shaped Parts詳細資料 -

Gear Parts詳細資料

Gear Parts詳細資料 -

Machinery & General Hardware Parts詳細資料

Machinery & General Hardware Parts詳細資料 -

Electric Parts詳細資料

Electric Parts詳細資料 -

Electric Parts詳細資料

Electric Parts詳細資料 -

Hand Tool Parts詳細資料

Hand Tool Parts詳細資料 -

Machinery & General Hardware Parts詳細資料

Machinery & General Hardware Parts詳細資料 -

Aluminum Forging Parts詳細資料

Aluminum Forging Parts詳細資料 -

Aluminum Forging Parts詳細資料

Aluminum Forging Parts詳細資料 -

Bicycle Parts詳細資料

Bicycle Parts詳細資料 -

Bicycle Parts詳細資料

Bicycle Parts詳細資料 -

Motorcycle Parts詳細資料

Motorcycle Parts詳細資料 -

Motorcycle Parts詳細資料

Motorcycle Parts詳細資料